The Comprehensive Guide to Label Printer Applicators

Introduction to Label Printer Applicators

In the fast-paced world of printing services, efficiency and accuracy are paramount. This is where the label printer applicator steps in as a game-changer. This technology streamlines the application of labels, making it an essential tool for various industries, including retail, manufacturing, and logistics. In this guide, we will delve into the functionalities, advantages, and applications of label printer applicators, helping you understand why they have become a cornerstone in modern business operations.

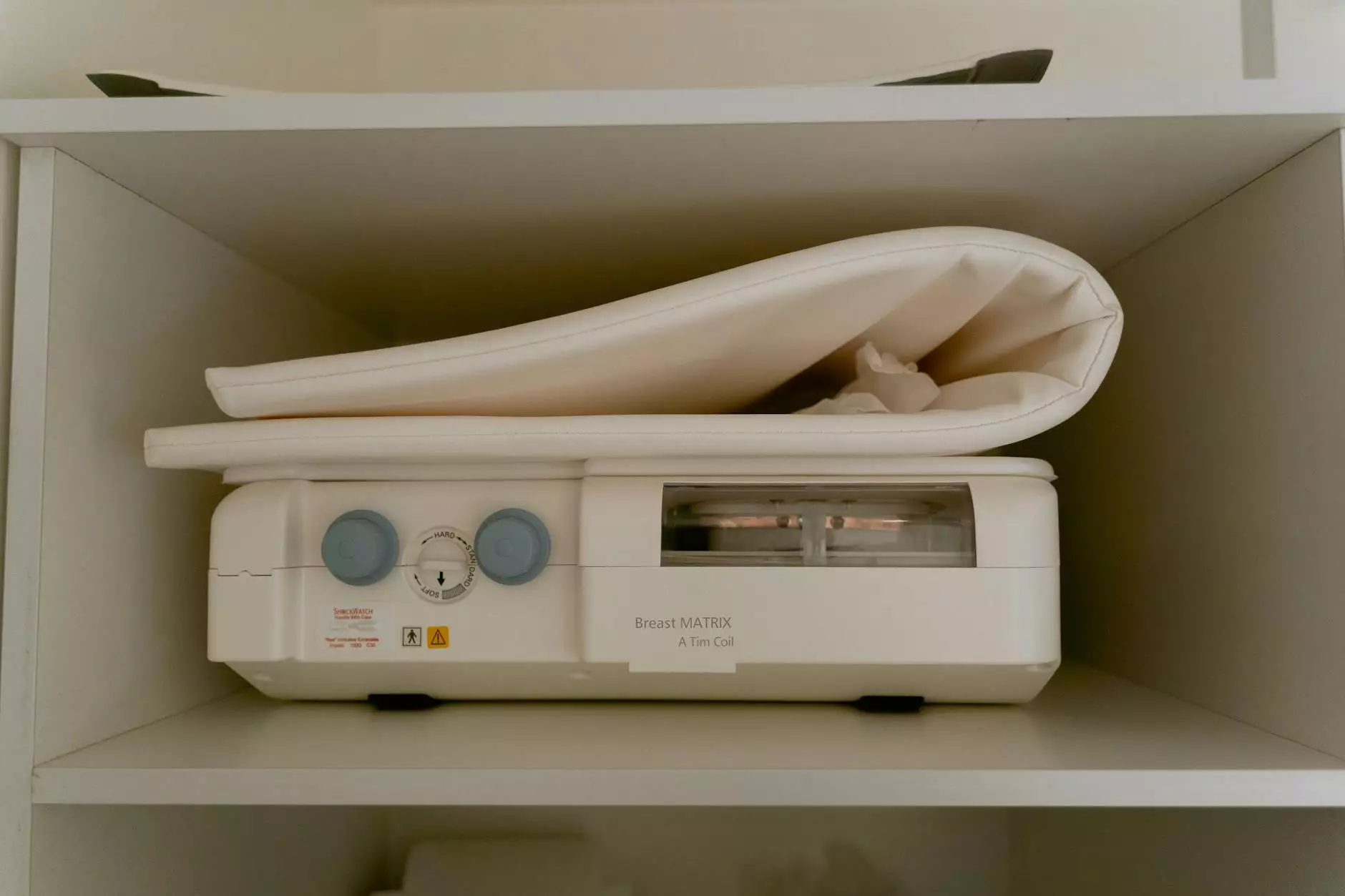

What is a Label Printer Applicator?

A label printer applicator is an automated device that prints and applies labels to products, packages, or pallets. These machines are designed to increase the speed and accuracy of the labeling process, which is often a critical aspect of product packaging and distribution. By automating this task, businesses can minimize human error, reduce labor costs, and significantly improve productivity.

Key Components of Label Printer Applicators

Understanding the components of a label printer applicator can help you appreciate its functionalities:

- Printer Head: The component responsible for printing the label. It uses thermal printing technology for high-quality results.

- Label Dispenser: Mechanism that feeds labels to the applicator. This can be a simple roll or a more sophisticated system that handles various label sizes.

- Controller: The brain of the machine, managing the timing and operation of the printing and application process.

- Application Arm: The part that positions and applies the printed label onto the product.

- Integration Ports: For connecting the applicator to other systems, such as inventory management software.

How Does a Label Printer Applicator Work?

The operation of a label printer applicator can be broken down into several straightforward steps:

- Design and Printing: A label design is created and sent to the printer section. This includes product information, barcodes, and branding.

- Label Dispensing: Once printed, the label is automatically fed to the application arm.

- Application: The application arm aligns the product in the correct position and applies the label, ensuring proper adhesion and placement.

Benefits of Using Label Printer Applicators

Investing in a label printer applicator offers numerous advantages:

- Increased Efficiency: These machines can operate at high speeds, continuously producing and applying labels without the need for breaks.

- Cost-Effective: By reducing labor costs associated with manual labeling, businesses can save significantly over time.

- Improved Accuracy: With precise application and reduced human error, the accuracy of labels—which often contain vital information—is significantly enhanced.

- Versatility: Label printer applicators are adaptable to various products and surfaces, enabling businesses to label a wide range of items.

- Streamlined Workflow: Automating the labeling process frees up employees for other tasks, enhancing overall productivity.

Types of Label Printer Applicators

Label printer applicators come in various forms, each serving different needs:

1. Cold Glue Applicators

These applicators use a cold glue system to apply labels, making them suitable for bottles and cans in the beverage industry.

2. Hot Melt Applicators

Utilizing hot melt adhesive, these are ideal for products that require a strong bond, such as heavy-duty boxes.

3. Pressure-Sensitive Label Applicators

These optimally apply labels that have a sticky backing, ideal for a variety of surfaces and products.

4. Print-and-Apply Systems

These integrated systems perform both printing and application tasks, ideal for high-volume and on-demand labeling requirements.

Choosing the Right Label Printer Applicator for Your Business

Selecting the appropriate label printer applicator is crucial for optimizing your operations. Here are some considerations:

- Volume of Labels: Assess how many labels you print and apply daily; higher volumes may require more advanced machinery.

- Type of Products: Consider the type of items you need to label. Certain applicators are better suited for specific product shapes and sizes.

- Integration: Ensure the applicator can seamlessly integrate with your existing production lines or inventory management systems.

- Budget: Analyze your financial capacity for both initial purchase and ongoing maintenance costs.

- Support and Service: Look for vendors that provide strong customer support and service options.

Applications of Label Printer Applicators in Various Industries

Label printer applicators are utilized across various industries:

1. Retail

Fast-paced retail environments benefit from the rapid application of labels on products, providing essential pricing, promotional, and compliance information.

2. Food and Beverage

In the food and beverage sector, accurate labeling is vital for safety and compliance. Label printer applicators ensure each product is labeled correctly and efficiently.

3. Pharmaceuticals

The pharmaceutical industry requires precise labeling for tracking and safety. Automating this process reduces the risk of errors.

4. Logistics and Distribution

In logistics, speed is critical. Label printer applicators ensure packages are labeled for quick identification and tracking throughout the shipping process.

5. Manufacturing

Manufacturing facilities use these applicators to ensure all components and products are correctly labeled for compliance and quality assurance standards.

Future Trends in Label Printing Technology

As technology evolves, so do label printer applicators. Here are some trends to watch:

- Smart Technology: Integration of IoT will allow for real-time monitoring and analytics, enhancing operational efficiency.

- Sustainability: With increasing emphasis on eco-friendly practices, manufacturers are creating more sustainable printing options.

- Custom Solutions: Modular systems allow for tailored solutions that meet specific business needs, improving versatility.

- Cloud Integration: This offers seamless operations and data management through centralized systems.

Conclusion

In conclusion, investing in a label printer applicator is an important step for businesses aiming to streamline their labeling processes. With the benefits of increased efficiency, accuracy, and cost savings, label printer applicators serve as vital tools across multiple industries. As technology advances, these machines will continue to enhance the way businesses operate, ensuring they stay competitive in a rapidly changing market. For companies in sectors such as printing services, electronics, and computers, adopting label printer applicators can transform operational workflows and drive revenue growth.

Explore Our Services at Omega Brand

At Omega Brand, we understand the needs of your business and offer tailored solutions involving label printer applicators and other printing services. Contact us today to learn more about how we can help you align your operations with industry standards and future trends!