The Importance of Prototype Injection Molds for Metal Fabricators

As Metal Fabricators strive for excellence in the production of high-quality parts, prototype injection molds play a crucial role in the development and testing process. Let's dive deep into the significance of prototype molds within the Metal Fabrication industry.

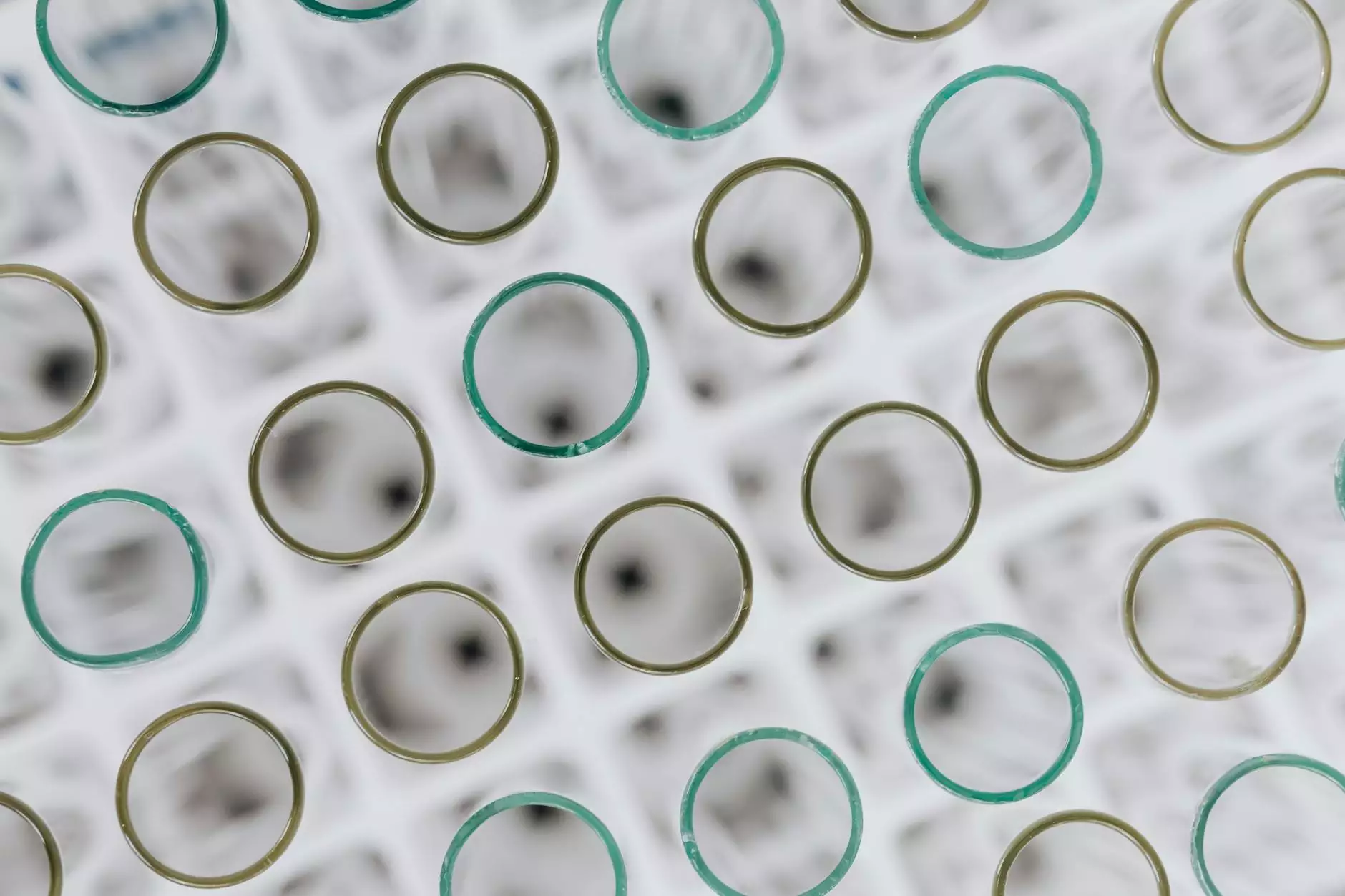

Understanding Prototype Injection Molds

Prototype injection molds are a vital component in the manufacturing process of metal parts. They are precision tools that are used to create sample parts quickly and efficiently. These molds enable Metal Fabricators to test designs, materials, and processes before full-scale production begins. By having functional prototypes, Fabricators can identify and rectify any issues early on, thus saving time and resources in the long run.

Benefits of Prototype Injection Molds

Investing in prototype injection molds offers numerous advantages to Metal Fabricators:

- Rapid Iteration: With prototype molds, Fabricators can iterate designs quickly based on feedback and testing results.

- Cost Savings: Detecting and resolving design flaws during the prototyping stage can significantly reduce production costs.

- Quality Assurance: Prototyping helps ensure that the final product meets quality standards and specifications.

- Time Efficiency: By identifying issues early, Fabricators can streamline the production process and meet deadlines effectively.

Application of Prototype Injection Molds in Metal Fabrication

From creating complex geometries to testing material durability, prototype injection molds are utilized in various Metal Fabrication processes:

1. Design Validation

Prototype molds allow Fabricators to validate designs and make necessary adjustments before moving forward with full-scale production. This ensures that the final product meets customer requirements and industry standards.

2. Material Testing

By using prototype molds, Metal Fabricators can test different materials to determine the most suitable option for the desired application. This helps in optimizing performance and durability.

3. Tooling Optimization

Prototyping molds assist Fabricators in refining tooling and manufacturing processes, resulting in enhanced efficiency and productivity within the facility.

Choosing the Right Prototype Injection Molds

For Metal Fabricators looking to invest in prototype injection molds, it is essential to consider key factors such as:

- Accuracy and Precision

- Material Compatibility

- Lead Time

- Cost-effectiveness

By selecting the appropriate molds, Fabricators can ensure seamless production and superior product quality.

Conclusion

Prototype injection molds serve as an invaluable tool for Metal Fabricators seeking to innovate, optimize, and deliver exceptional products in a competitive market. Embracing prototyping technology allows Fabricators to stay ahead of the curve and meet the ever-evolving demands of the industry.